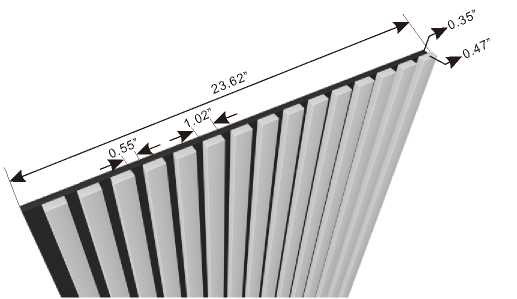

Dimension

Consists of a 0.35" black or grey recycled PET Polyester acoustic fabric on which are mounted 1.02" x 0.47" strips in colored dark brown or black recycled MDF veneered with real wood veneer. The strips are spaced 0.55" apart.

Each box contains one panels, both measuring 94.48" x 23.62". These panels will join next to each other seamlessly.

Each box covers:

•94.48"/ 2400mm (H)

•23.62"/ 600mm (W)

•0.82"/ 21mm (D)

Properties of real wood veneer

Natural wood veneer can vary in color, grain structure and appearance from strip to strip and panel to panel.

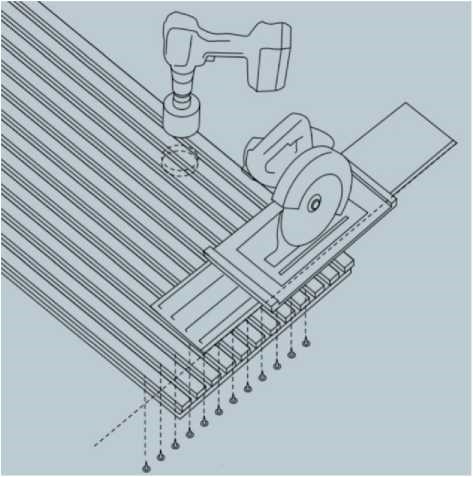

How to cut and drill

When sawing or drilling the acoustic panel, it is recommended that you first tape the area where the cut is made

should be with regular masking tape. Screw or staple the slats 50 mm inside the intended saw cut. Use a fine-toothed hand saw for veneer or a countersink/circular saw with a fine-toothed blade equipped with a guide rail for best results. Carefully sand the cut with sandpaper (fine-grained 240).

The polyester fabric of the acoustic panel is easily cut with a sharp blade.

Care and maintenance

We recommend adding a protective finish to the panels if possible. Something like wood oil is perfect as it protects and keeps the natural look and feel of the wood. Once this is applied, light dusting or hovering will prevent any dust build-up. If you choose to keep the panels without a finish, then a dry cloth can wipe the panels down.

Fire rating

The acoustic felt backing carries a class A fire rating following certification ASTM E84-16.

How to install

There are three different options for installing

1.Gluing straight onto the wall:

A construction glue or grab adhesive is recommended for this.

2.Screwing directly into the wall:

Using black screws for the black backing option or silver or grey screws for the grey backing, the panels can be screwed directly into the wall through the acoustic felt.

We recommend a minimum of 9 screws per panel at 3.15" intervals across the width and 24" intervals down the length of the panel.

If installing into ceilings, make sure they are screwed into ceiling joists. Please make sure the correct fixings are used if going into plasterboard, for example.

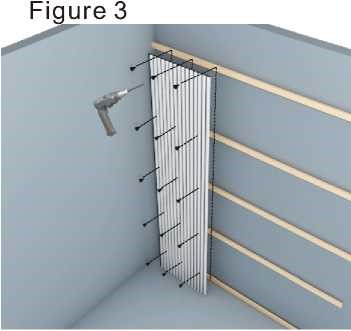

3. Screwing the panels into 1.8" timber battens:

We recommend screwing 1.8" timber batons to the wall and then screwing the panels directly into the batons through the acoustic felt to achieve optimum sound absorption.Combined with Rockwool behind the panels between the batons, this will achieve Class A sound absorption.

4. As shown in the picture, install the light steel keel on the wall with a distance of 3.94" from the wall, and the recommended distance between the vertical keel is 23.6", and the horizontal keel can be adjusted according to the actual situation.

The middle of the keel needs to be filled with sound insulation cotton to obtain a more perfect sound absorption effect.

The product can be fixed on the keel by screws.

Technical Drawing

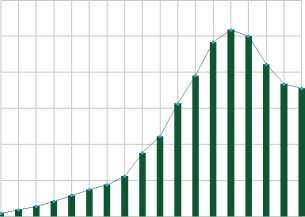

Figure 1

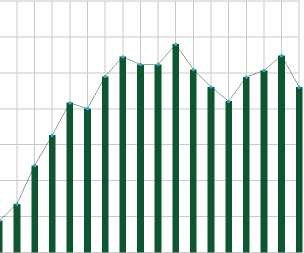

Figure 2

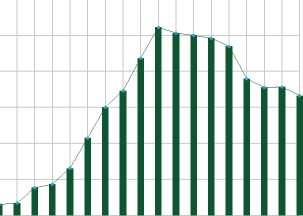

Figure 3

Figure 4

Sound Absorption Coeffcient for Acoustic Panels.

Laboratory measurements of sound absorption coeffcient were carried out in a reverberation room according to the test method of EN ISO 354:2003.

Panel mounted directly to the wall

As seen in the graph, the 0.82" panel, mounted directly to the wall, obtains an absorption coefficient of 0.3 (MH).

Panel mounted with 1.8 timber batons spacing and mineral wool insulation

As seen in the graph, the 0.82" panel, mounted with 1.8"timber batons spacing and mineral wool insulation,obtains an absorption coefficient of 0.62 (MH).

Panels mounted on 3.94" pitch light steel joists and filled mineral wool

insulation

As shown, the panels were mounted on light steel joists with 3.94" spacing from the wall and filled with mineral wool insulation for an absorption coefficient of 0.95 (MH).